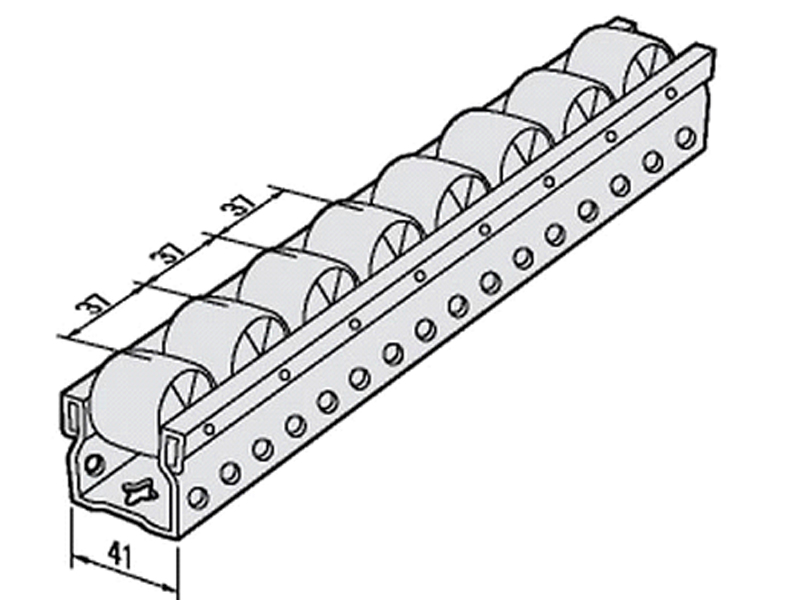

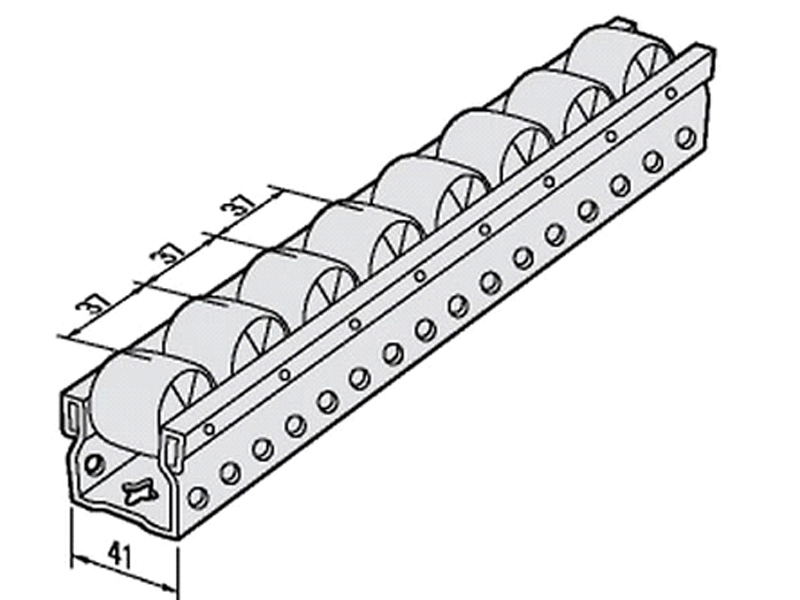

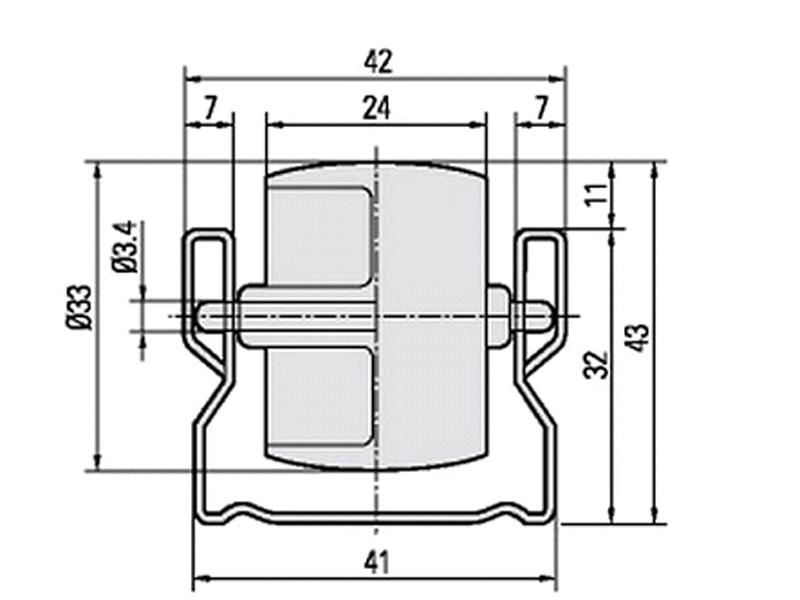

GP-40A

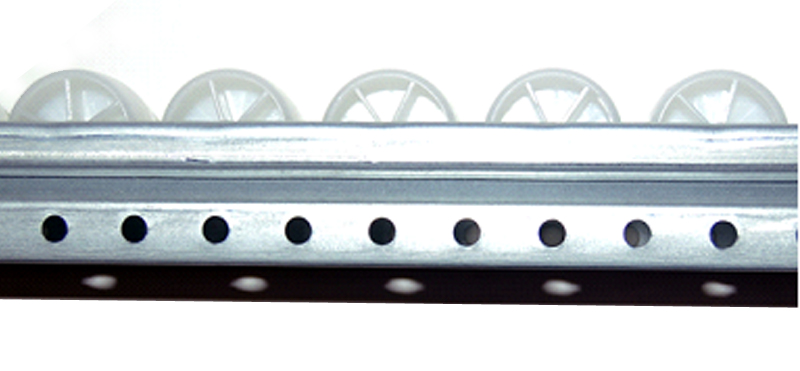

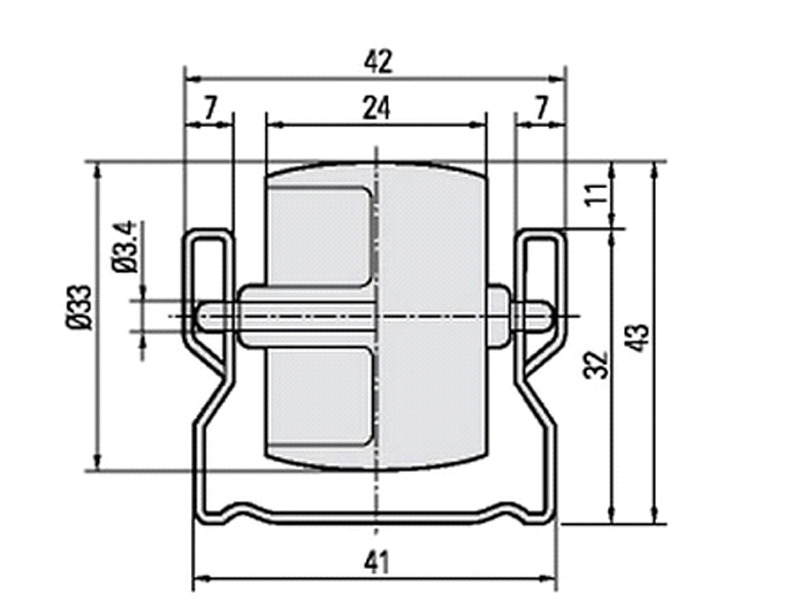

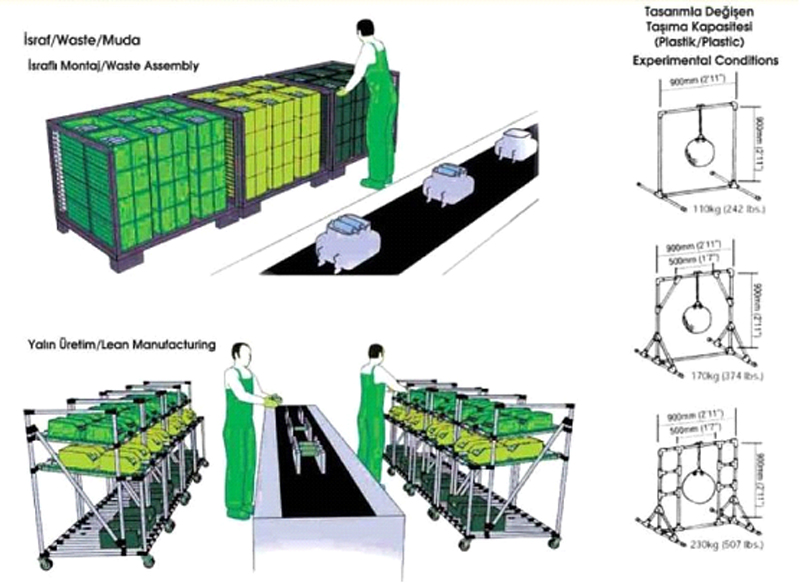

Roller rails are rail profiles that allow the products to slide in a free flow manner. They are in various sizes and serve as a guide for guiding purposes. GP40A roller rail is used in various applications in the automotive, wood, printing and panel production sectors thanks to its 40 mm base and stable profile structure. They are 4 mt in length and the unit price is the price of 1 mt.

In addition to the significant contribution of the process development, it helps you to rise the competitiveness of yours by making the processes faster.

From a "kaizen" (making better) point of view, it is useful in terms of predetermined thinking, direction and statistics for problem detection.

8 Losses that make the equipment inefficient:

1) Failure: These are the downtimes that cause the machine or a production line to stop and last longer than 3 minutes.

2) Set-up: It is the time that occurs during model change and/or assembly of parts to workbenches and until the first quality product is obtained.

3) Tool change: These are the stops that occur during the replacement of broken or worn blades, tips or tools as a result of long use.

4) Start: It is the time until the equipment is ready for the first production, especially in equipment that needs to be warmed up or in a regime before starting to work. All the downtimes that occur at the beginning of the working hours and from the machines until the first quality product is obtained can also be evaluated within this scope.

5) Small stoppages and idle time: These are the stops that cause the machine or production line to stop and last up to 3 minutes.

6) Speed: These are the losses that occur when the machine is operated at a slower speed instead of the optimum speed determined for the product in production.

7) Faulty production and repair: It is the time, parts and materials spent for the repair of the faulty product.

8) Machine shutdown: All previously known machine shutdowns.

Download Certificates

444 00 42

444 00 42

.jpg)