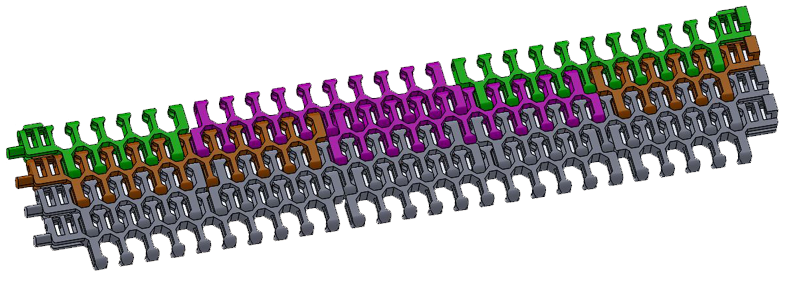

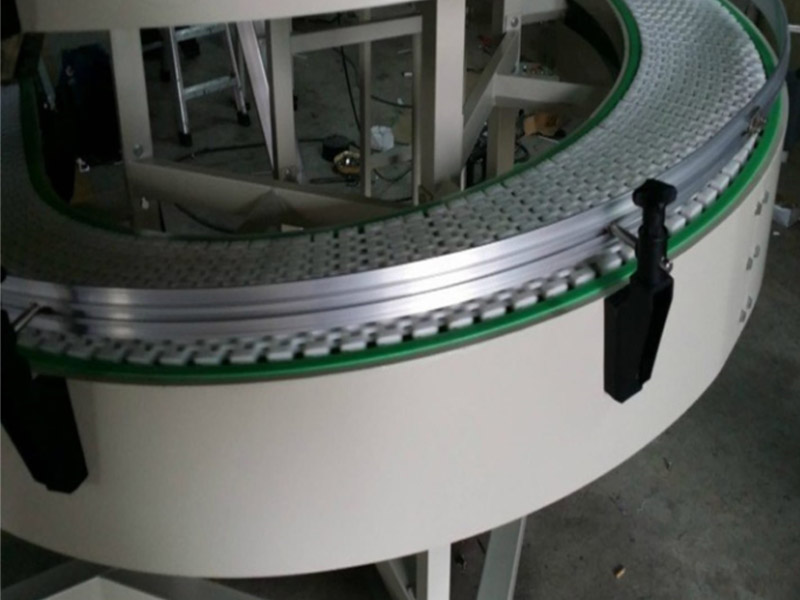

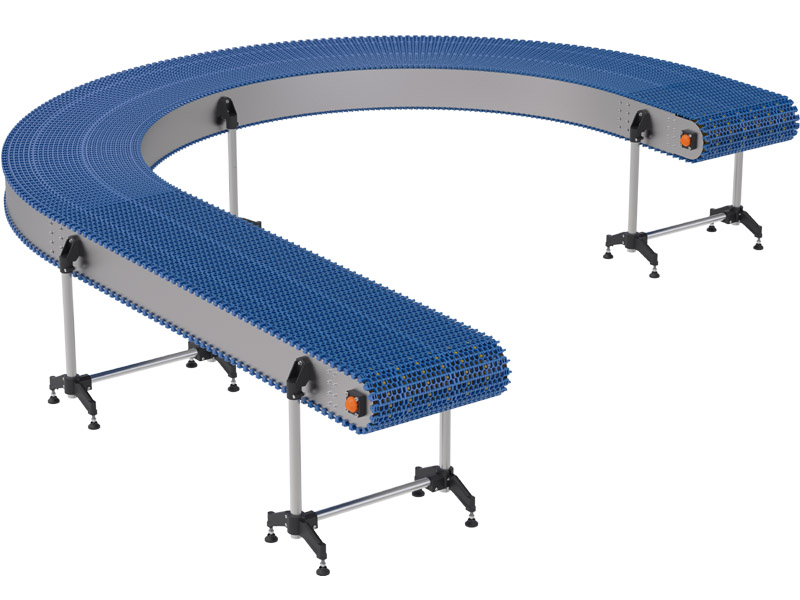

941 50,8mm SPIRAL MODULAR BELT

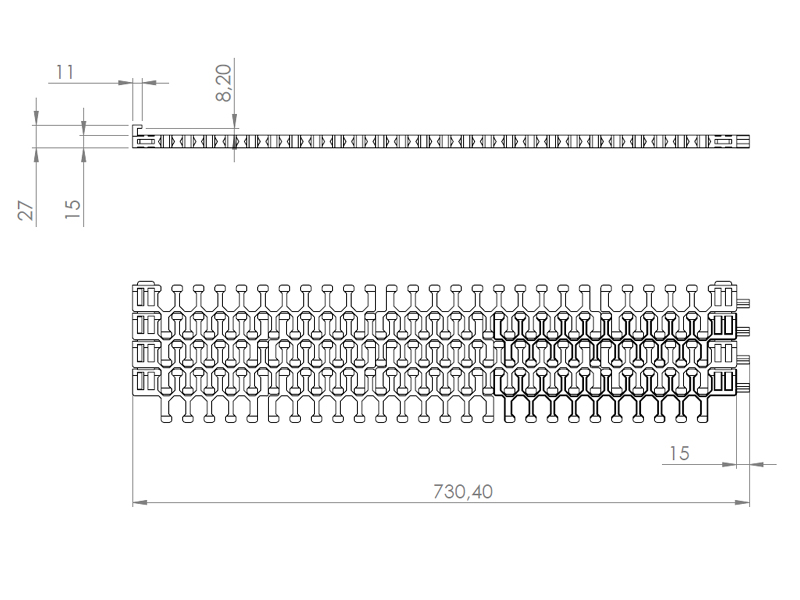

| Pitch | 50.8mm |

| Thickness of Belt | 15mm |

| Open Surface Ratio (%) | Open Surface (%50) |

| Width of the Module | Right: 287,08 /160,75mm / Middle: 266,07mm / Left: 176/303,08mm |

| Widthness | 127mm - 254mm - 381mm - 508mm - 635mm - 762mm - 889mm - 1016mm - 1143mm - 1270mm |

| Colour | White/Blue/Gray |

| Cleanability | Good (FDA Food Grade) |

| Pin Diameter | 6,40mm |

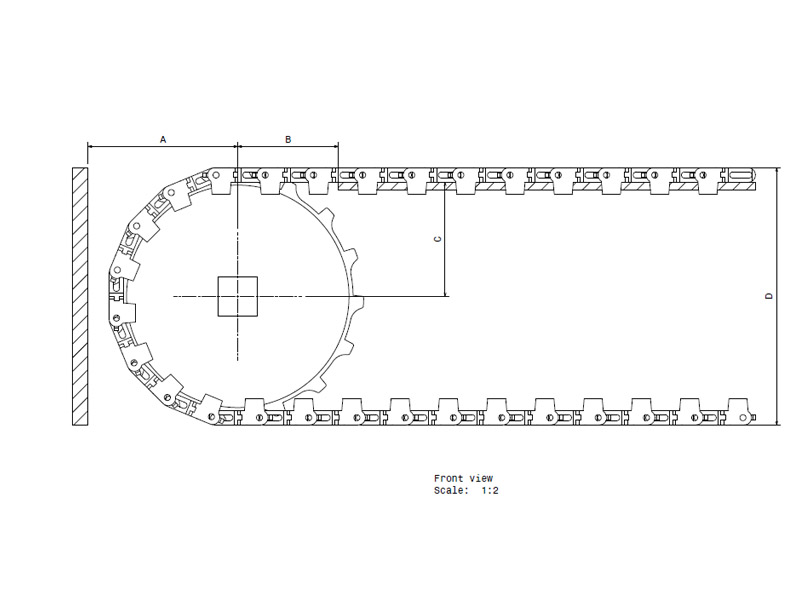

| Major Radius | Up to the Sprocket Preference |

.jpg)

| Stock Code | Belt Width L mm |

Return Rate | Return the Internal Radius Ratio |

Return the External Radius Ratio |

|---|---|---|---|---|

| 941 B01 K08 | 127 | 1,8 | 228,6 | 355,6 |

| 941 B01 K09 | 254 | 457,2 | 711,2 | |

| 941 B01 K10 | 381 | 685,8 | 1066,8 | |

| 941 B01 K11 | 508 | 914,4 | 1422,4 | |

| 941 B01 K12 | 635 | 1143 | 1778 | |

| 941 B01 K13 | 762 | 1371,6 | 2133,6 | |

| 941 B01 K14 | 889 | 1600,2 | 2489,2 | |

| 941 B01 K15 | 1016 | 1828,2 | 2844,8 | |

| 941 B01 K16 | 1143 | 2057,4 | 3200,4 | |

| 941 B01 K17 | 1270 | 2286 | 3556 |

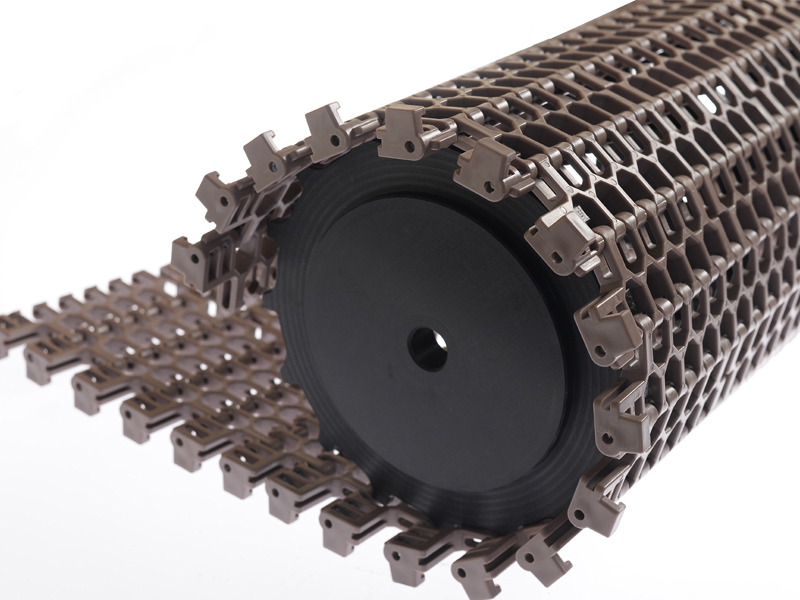

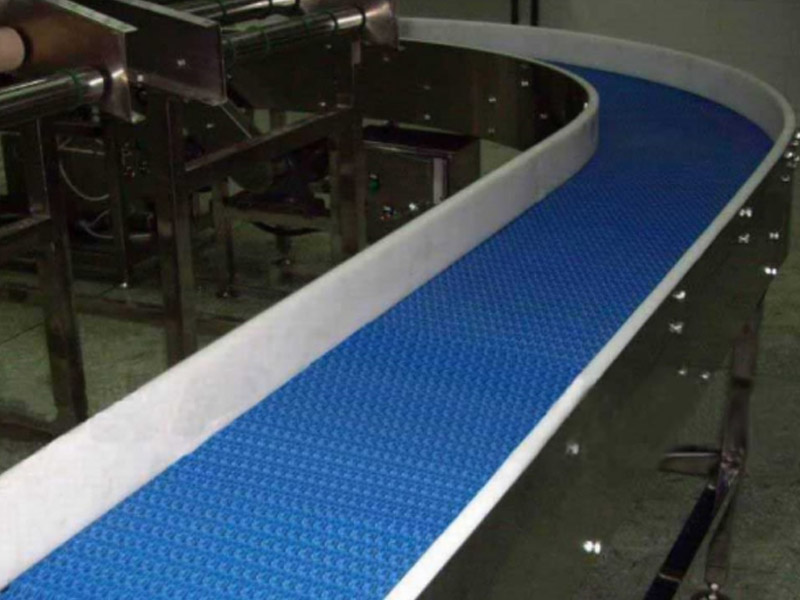

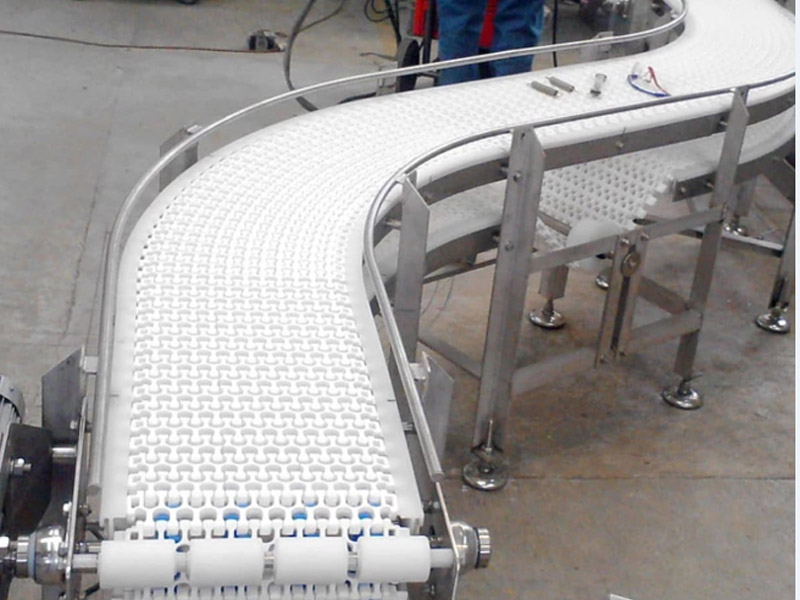

941 spiral rotating ALHAN plastic belts have 1.8x tape width as turning diameter. With a pitch of 50.8 mm and an opening area ratio of more than 50%, it has brought a new breath to the spiral conveyor world. It also has a different working status with its actiondrive feature, it can rotate the spiral without turning the drum from the middle. It is ideal for shocking, freezing, resting and accumulation lines. It is also preferred in complete IQF and Freezer systems together with spiral conveyors. It can travel long distances in small areas with the logic of short passing in narrow areas.

Due to the lack of product knowledge of the designers, wire tape is considered as the solution to all problems. Wire belts are quite heavy due to its nature. However, ALHAN plastic belts are light. Since wire belts are heavy and not resistant to friction, they wear out quickly and increase costs as they do not allow local repairs over time. ALHAN Plastic belts, on the other hand, are light and resistant to friction, so they do not wear easily and do not damage the bearing material. Because corrosion is not a one-sided relationship, stainless wire belts have limited resistance to various chemicals and solutions, and there is a possibility of corrosion. Alhan Plastic belts, on the other hand, are resistant to various chemicals and solutions thanks to their hydro-carbon structure. Since the wire belts do not show the problem immediately while they are running, the continuation of the transmission in the event of danger causes possible damage to the drive group and causes the chain to lengthen permanently. ALHAN Plastic chain and modular belt break due to a certain safety factor by nature, and it PROTECTS THE SYSTEM. The system stops with the least damage, it acts as a kind of insurance.

Contrary to popular belief, the tensile strength of wire belt is lower than plastic belt and mesh tape. ALHAN plate chains and modular belts have a stable material structure, so it does not wear out immediately. Due to the weight of the wire band, it consumes high energy while moving. The plastic product is very light and slippery. Therefore, it is a savings-oriented and maintenance-friendly product choice.

The industrial areas of the usage of 50.8mm spiral modular belt;

- Food Industry

- Automative Industry

- Meat Industry

- Pharmaceutical Industry

- Becerage Industry

- Fruit and Vegetable Sector

- Canned Food Industry

- Sea Products

- Confectionary Industry

- Packaging Industry

- Corrugated Cardboard Sector

- Bakery Products

| Polypropilen (PP) | +1 | +110 |

| Polyacetal (POM) | -40 | +70 |

| Polyethylene (PE) | -60 | +65 |

İndirDownload 3D File Download Certificates

444 00 42

444 00 42

.jpg)

.jpg)